¶ Lithium-Ion batteries and fuses

Every electrical system needs protection from potential abuse. A common way to protect electrical circuits against short-circuit and over-current, is using a fuse.

Basically a fuse is a piece of metal that melts at a predefined temperature, which is related to a current rating. There are a lot of different fuses available with all their specific properties for a certain application.

In this technical note only a small part will be discussed that is dedicated to battery fusing. It summarize the basic properties of fuses in combination with battery systems.

¶ Introduction

In a battery system and in particular a Lithium-Ion battery system, fusing is an important part of the electrical system design. Lithium-Ion batteries have a very low internal resistance and this results in a high short-circuit currents. A battery is also an energy source that cannot be switched off.

The fuses in a battery systems may have the following functions:

- Short-circuit protection.

- Over-current protection.

Both functions will protect not only the battery itself, but also the cables that it is connected with.

Always take into account the regulation applied for the specific application when designing an electrical system with batteries.

¶ Electrical battery system design

Most Lithium-Ion battery systems are designed with basic parameters like the energy capacity, voltage and maximum current or power. For example an electric motor of 20 kW / 48 V needs to operate on a battery bank for 3 hours. The energy capacity would then be 3 x 20 kW = 60 kWh. The battery bank is configured at 48 V which results in a maximum current of 20 kW / 48 V = 416 A. In this case we took the 48 V as the lowest battery voltage. This will result in the highest current. It depends on the battery type and model which voltage is the minimum.

¶ Specifications for battery fuses

When from the battery system design the current and voltages are known, there are other specifications for selecting the correct fuse. The selecting of the fuse with the correct properties is depending on the application and function of the fuse.

¶ Rated voltage

This is the maximum voltage the fuse can safely interrupt when it blows.

The fuse's voltage rating must be equal to or greater than the maximum voltage of your battery system. If the fuse's voltage rating is too low, arcing can occur across the blown fuse, leading to continued current flow, damage, or fire.

¶ Rated current

This is the maximum current the fuse can carry continuously without blowing.

It should be greater than the normal operating current of your circuit. A common rule of thumb is to select a fuse with a rating 25-30% higher than the continuous operating current to account for temporary surges and prevent "nuisance" blowing. However, it must also be lower than the current-carrying capacity of the cable it's protecting. The fuse's primary role is to protect the wiring from overheating and potential fire.

¶ Interrupting Rating (Breaking Capacity / Short Circuit Rating)

This is the maximum fault current the fuse can safely interrupt without rupturing or causing an explosion. In Lithium-Ion battery systems the short-circuit currents can be significantly high.

The fuse's interrupting rating must be greater than the maximum possible short-circuit current that the battery system can deliver.

¶ Time-current Characteristic

This describes how quickly the fuse reacts to an over-current condition.

Fuses can react fast to an already small (10%-20%) over-current situation to protect sensitive electronics like motor controllers and inverters. These are the so-called semiconductor fuses. There are also fuses that can handle cycling

over-currents and will only blow when a significant over-current situation occurs like during a short-circuit.

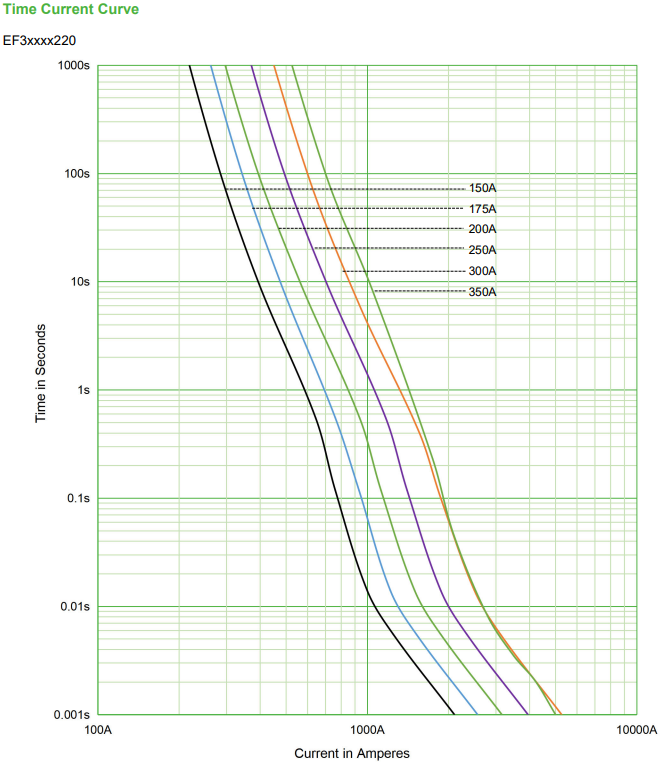

Example timing curve of a high interrupt rating fuse:

The time of opening the circuit can be found with this timing curve, the fuse's rated current and the short-circuit current of the Lithium-Ion battery system.

¶ Ambient temperature

Fuses are temperature-sensitive devices. Their current ratings are typically specified at 25°C. Always check the ratings of the fuse at the application's ambient temperature. Higher ambient temperatures can cause a fuse to blow at a lower current rating.

¶ Fuses comparison

The differences of the basic fuse properties are shown in the comparison table below. In table the comparison is made with a specific 300 A current rated fuse.

| Feature | T-Class Fuse (e.g., Littelfuse JLLN, Blue Sea Systems) | Adler EF3 EV Fuse | MEGA Fuse (Littelfuse 58V Series) | A15QS Fuse (Mersen Amp-Trap) |

|---|---|---|---|---|

| Article number | JLLN300 | EF33300220 | 14.253.956.302 | A15QS300-4 |

| Description | Class T Fuses JLLN Series |

Adler EF3 series EV fuses up to 315 Vdc in ratings from 150A to 700A. | BF2 Series Bolt-down Fuses – Rated 58V |

High Speed Fuse Amp-Trap® A15QS 150VAC 150VDC 300A Blade |

| Voltage rating | 125 Vdc | 200 Vdc | 58 Vdc | 150 Vdc |

| Current rating | 300 A | 300 A | 300 A | 300 A |

| Interrupting current (IR) / Breaking capacity | 20 kA | 50 kA | 1 kA | 50 kA |

| Time at 4 kA (typical short-circuit current of Lithium-Ion LFP battery module) | < 0.01 s | 0.0025 s | Cannot handle 4 kA | < 0.001 s |

¶ Common practice for MG battery systems

One of the common practices is to use always a high breaking current fuse on the battery side. This means that in case of using an MG Master LV, a high breaking current fuse will be installed on the battery side and a regular MEGA fuse will be installed on the Charger/Loads side.